Toyota’s Technical Information System (TIS), often referred to as Tis Toyota One, is a crucial resource for collision repair professionals. It provides detailed repair procedures, specifications, and other essential information needed to properly repair Toyota vehicles. This article will explore the importance of using TIS Toyota One, specifically focusing on occupant classification system (OCS) calibration and blind spot monitor (BSM) angle adjustment.

TIS Toyota One offers comprehensive repair manuals that outline the necessary steps for various procedures. As highlighted by Eric Mendoza of Toyota collision operations at the SCRS OEM Collision Repair Technology Summit, referencing the official repair manual is paramount. Determining if an OCS reset is required depends on the specific vehicle and situation.

Understanding Occupant Classification System (OCS) Calibration with TIS Toyota One

The OCS utilizes sensors to evaluate the weight in the front passenger seat to determine airbag deployment in a collision. A miscalibrated sensor can lead to improper airbag deployment, potentially causing harm. TIS Toyota One provides precise instructions for OCS calibration.

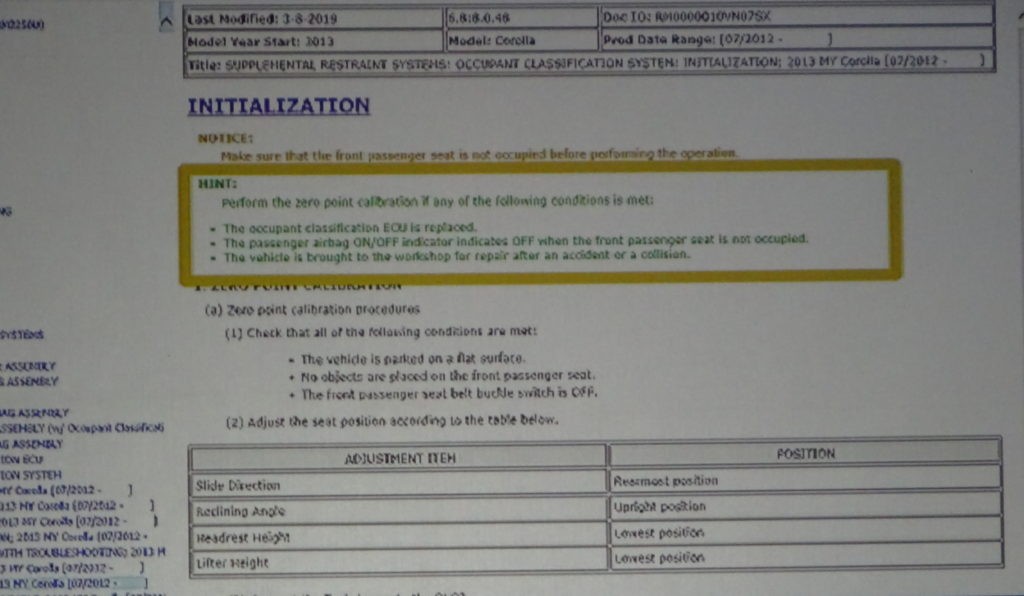

For example, a 2013 Corolla requires a zero-point calibration after a collision, ECU replacement, or if the passenger ON/OFF indicator malfunctions. Accessing TIS Toyota One, navigating to Vehicle Interior >> SUPPLEMENTAL RESTRAINT SYSTEMS >> OCCUPANT CLASSIFICATION >> INITIALIZATION will reveal these specific instructions.

However, procedures can vary between model years. A 2017 Corolla requires calibration under different circumstances, such as seat removal, bolt replacement, or specific diagnostic trouble codes (DTCs) related to the OCS.

Consulting TIS Toyota One for each repair ensures the correct procedure is followed, regardless of the model year.

Blind Spot Monitor (BSM) Angle Adjustment Procedures in TIS Toyota One

Another critical procedure outlined in TIS Toyota One involves the BSM. When replacing a quarter panel, the BSM must be removed to avoid damage. Upon reinstallation, an angle installation inspection is crucial for proper functionality. This involves verifying the precise angle of the BSM using a specialized gauge available from Toyota.

This process, distinct from calibration, ensures accurate BSM operation. TIS Toyota One details this procedure, including the use of the specialized gauge or alternative methods using a plumb bob and string.

Utilizing TIS Toyota One for Complete and Accurate Repairs

TIS Toyota One provides access to critical information, ensuring proper and safe repairs. By consistently referencing TIS Toyota One for procedures like OCS calibration and BSM angle adjustment, technicians can maintain the highest standards of quality and safety. Accessing the most up-to-date information ensures accurate repairs, contributing to customer satisfaction and safety. Remember to always consult TIS Toyota One for every repair to ensure adherence to manufacturer specifications.