The Mt Pro 4 is a powerful automotive lab scope designed for diagnosing internal combustion engines and various vehicle systems across all makes and models. This comprehensive diagnostic tool allows mechanics to visualize changing signals within wires and analyze internal engine processes, providing valuable insights into vehicle performance. The MT Pro 4 software boasts essential features like an oscilloscope, spectrum analyzer, and specialized tests for automotive signals, including secondary voltage, in-cylinder pressure, engine compression, and battery/starter/charging system analysis, along with a power balance test.

MT Pro 4 Hardware: Built for Durability and Precision

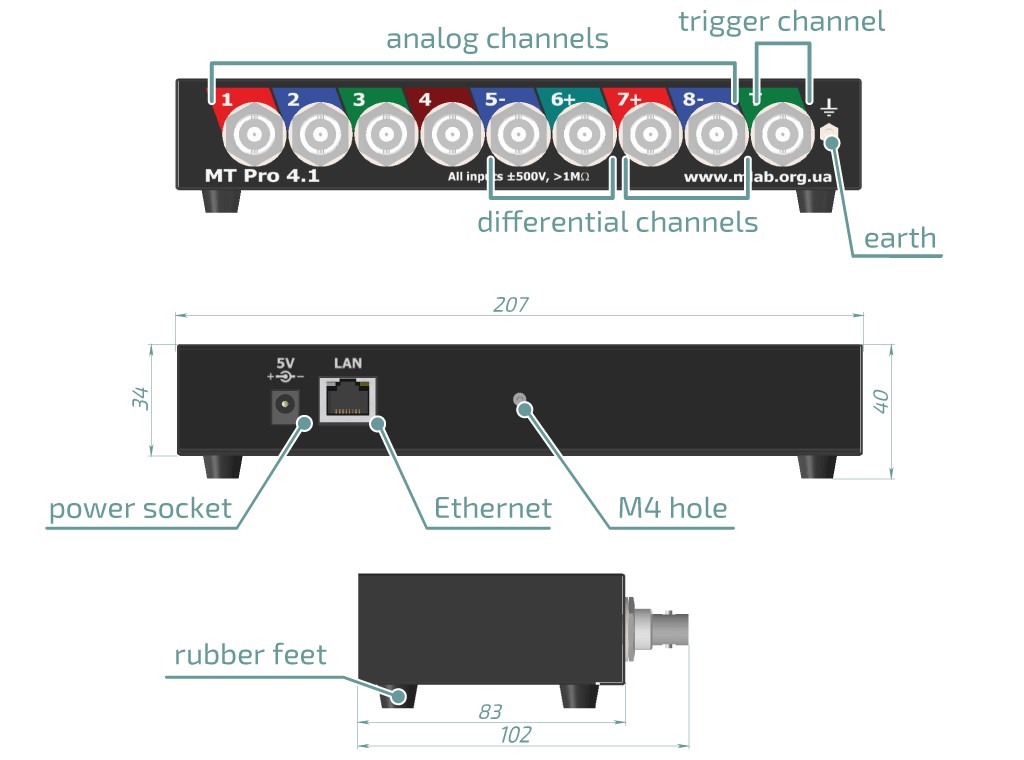

The MT Pro 4 is housed in a robust, impact-resistant metal casing with a scratch-resistant powder coating, effectively shielding the device from external electromagnetic interference generated by high-voltage ignition circuits. The front panel features nine color-coded BNC connectors for analog and trigger channel connections, along with a grounding terminal. The rear panel includes a DJK-02 power connector, an RJ45 connector for PC connectivity, and a threaded hole for mounting. The meticulously designed printed circuit board minimizes interference from ignition and power circuits, ensuring accurate readings. The PCB is assembled using automated soldering for enhanced reliability.

The MT Pro 4 package includes:

- One MT Pro 4 oscilloscope

- One 5-meter shielded RJ45 FTP patch cord with a built-in USB power line

- One hanging hook for convenient device mounting

MT Pro 4 Software: A Suite of Powerful Diagnostic Features

The MT Pro 4 software offers a comprehensive suite of diagnostic capabilities, enabling in-depth analysis of various vehicle systems.

Oscilloscope Functionality

The oscilloscope function allows simultaneous data display from multiple analog channels and the triggering channel in Oscilloscope, Capture, and Recorder modes. Signals can be displayed in relevant physical units (pressure, current, etc.) for each analog channel.

Secondary Voltage Analysis

The software automatically analyzes primary and secondary ignition voltage signals captured using capacitive (Cx) or inductive (Lx) sensors. Signals can be displayed in parade, raster, or overlay formats for easy comparison.

Power Balance Testing

This comprehensive test identifies malfunctions causing unstable engine operation, calculates cylinder efficiency across various engine modes, detects misfires (including chaotic ones), and pinpoints the root cause (fuel system, ignition system, or engine mechanics).

In-Cylinder Pressure Analysis

This feature analyzes gasoline engine cylinder pressure, calculating key characteristics like compression ratio, combustion chamber leaks, gas distribution phase, cylinder fuel-air mixture efficiency, exhaust system efficiency (e.g., clogged catalytic converter), and ignition timing.

Cylinder Comparison

This function allows for convenient comparison of signals from all cylinders, visually highlighting deviations in operation. This visual comparison is universally applicable, as it relies on identifying signal differences rather than being tied to a specific signal type. It enables analysis of pressure pulsations in the intake manifold, exhaust pipe, fuel system, crankcase gas pressure, injector control signals, and other periodic signals.

Electrical Power Equipment Testing

This test assesses the condition of the battery, starter (including the solenoid relay and terminals), alternator (voltage regulator, rectifiers, and power circuits), and glow plugs (for diesel engines). Results are displayed in a single chart with numerical values and deviations.

Spectrum Analyzer

The spectrum analyzer performs spectral analysis of arbitrary signals and processes signals using a customizable digital filter. Signal spectrograms are generated based on time and crankshaft angle, facilitating comparison of noise from various internal combustion engine mechanisms.