Managing truck maintenance costs is crucial for fleet owners and repair shops. Unpredictable expenses can significantly impact profitability. For heavy-duty repair shops, understanding and accurately estimating labor costs is paramount for staying competitive and ensuring financial stability. This is where Mitchell1 Truck Series software comes in, providing data-driven solutions to help manage and predict repair costs.

One of the key features of Mitchell1 Truck Series is its comprehensive labor time estimating capabilities. The software leverages a vast database of industry standard labor times, allowing shops to benchmark technician performance and gain valuable insights into their operations. This data-driven approach transforms unknown variables into quantifiable metrics, enabling more accurate cost estimations and improved profitability.

Mitchell1’s labor times are developed using a proven methodology by a team of ASE certified labor editors with extensive trucking industry experience. They utilize field research, time studies, and industry best practices to determine how long a repair should take an average technician under normal conditions.

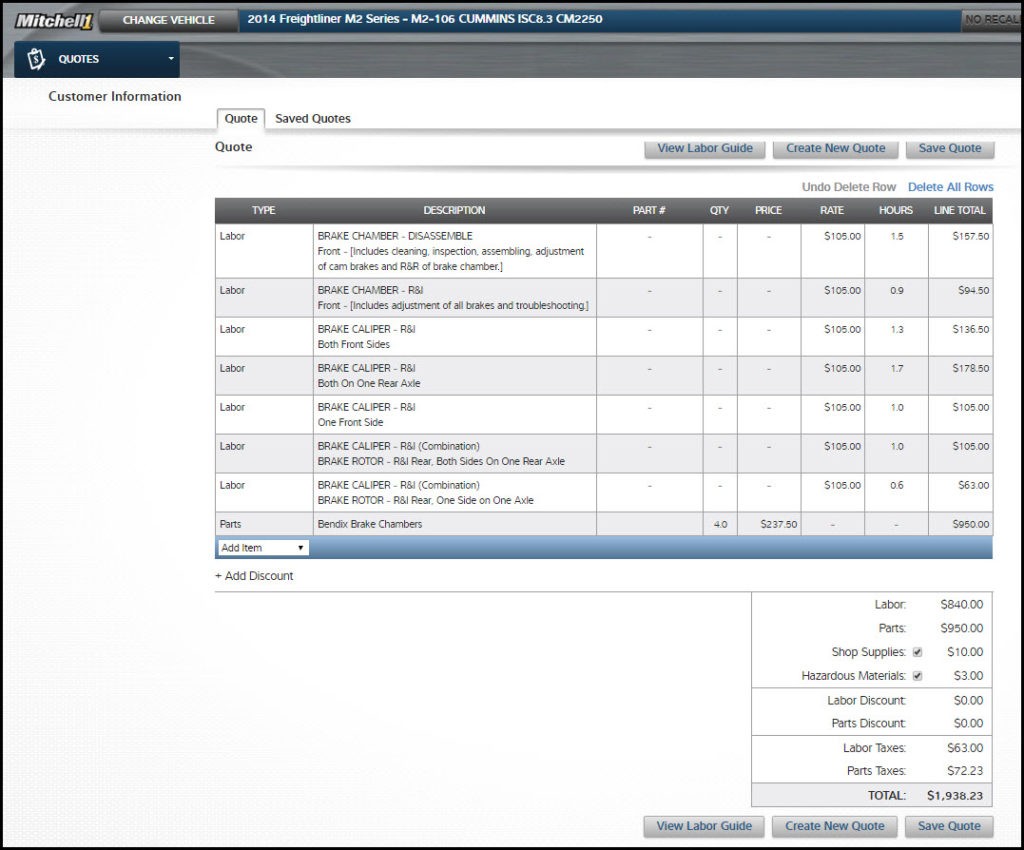

Mitchell1 Truck Series Product Screenshot

Mitchell1 Truck Series Product Screenshot

The TruckSeries Labor Guide allows technicians to quickly identify specific components and operations, accessing the corresponding labor times for repair or replacement. Recognizing that real-world conditions can vary, the software allows shops to adjust these times to reflect their specific circumstances. Factors such as technician experience, vehicle condition, equipment used, and even climate can influence the actual time required for a repair.

Mitchell1 Truck Series covers all makes and models of Class 4-8 trucks from model year 1990 to current. Repair categories include engines, brakes, electrical systems, HVAC, steering, suspension, transmission, driveline, axles, and accessories. This comprehensive coverage ensures that shops have the information they need to accurately estimate labor costs for virtually any repair.

Beyond internal use, this transparency can be extended to customers. Providing accurate and predictable service cost estimates builds trust and fosters stronger customer relationships. Mitchell1 Truck Series facilitates this by enabling personalized commercial truck repair estimates with customized labor rates for different customer types or service operations. The system’s intuitive interface simplifies the process of generating accurate estimates, allowing shops to quickly identify the year/make/model, select labor operations, add parts, and send the estimate to the customer or internal stakeholders.

In conclusion, Mitchell1 Truck Series empowers heavy-duty repair shops to effectively manage and control labor costs through data-driven insights and accurate estimating capabilities. The software’s comprehensive database, combined with its ability to customize labor rates and generate detailed estimates, provides a valuable tool for improving profitability and enhancing customer satisfaction. By leveraging the power of Mitchell1 Truck Series, repair shops can navigate the complexities of truck maintenance costs with greater confidence and efficiency.