John Deere equipment relies heavily on the Engine Control Module (ECM) for optimal performance. A malfunctioning ECM can lead to significant downtime and costly repairs. This article focuses on John Deere Ecm Repair, specifically for the L16 ECM found in models like the 7630, 7730, 7830, and others. We’ll discuss common problems, troubleshooting steps, and the benefits of professional repair services.

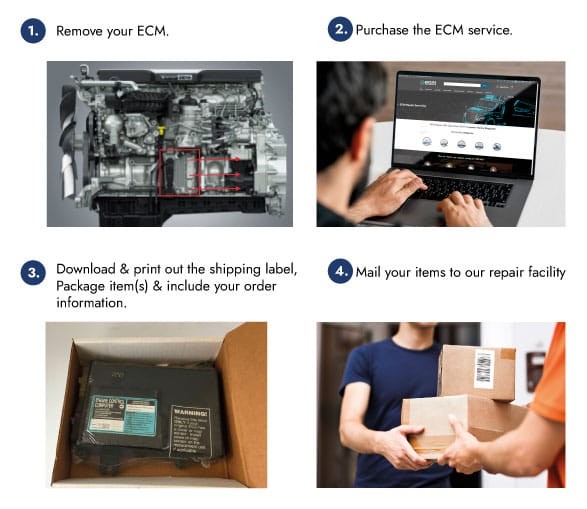

John Deere ECM Repair Process

John Deere ECM Repair Process

Common Problems with John Deere L16 ECMs

The John Deere L16 ECM, often identified by part numbers RE526588 and RE526587 (also replacing RE531808, SE502801, SE502800, and others), can experience a range of issues. Recognizing these symptoms can help in diagnosing the problem:

- Blown Fuses: A blown fuse might indicate a short circuit or overload within the ECM.

- No Communication: The ECM may fail to communicate with other systems, preventing proper operation. Diagnostic tools won’t be able to connect.

- Engine Shutting Down: Unexpected engine shutdowns can be caused by faulty ECM signals or internal errors.

- Fault Codes: The ECM will often log fault codes that can be retrieved using diagnostic equipment, providing clues to the problem.

- Intermittent Faults: Problems that come and go can be particularly challenging to diagnose and often point to loose connections or failing components within the ECM.

- Oil Intrusion: Oil leaking into the ECM housing can cause damage to the circuitry and lead to malfunction.

- Water Damage: Exposure to water can corrode the ECM’s internal components, leading to various operational issues.

The John Deere ECM Repair Process

Professional John Deere ECM repair involves a systematic approach to diagnose and fix the issue:

-

Inspection and Diagnosis: Technicians use specialized diagnostic tools to identify the root cause of the problem. This may involve checking for fault codes, measuring voltage and resistance, and visually inspecting the ECM for damage.

-

Component Replacement: If faulty components are identified, such as transistors, capacitors, or microcontrollers, they are replaced with genuine John Deere parts.

-

Circuit Repair: Damaged circuitry, including broken traces or burnt components, is carefully repaired using specialized soldering and micro-soldering techniques.

-

Reprogramming: In some cases, the ECM may require reprogramming to restore its factory settings or update its software. This requires specialized equipment and knowledge of John Deere software.

-

Testing: After the repair is complete, the ECM undergoes rigorous testing to ensure it functions correctly under various operating conditions. This may involve simulating real-world scenarios to verify its reliability.

Benefits of Professional John Deere ECM Repair

Choosing a professional repair service for your John Deere L16 ECM offers several advantages:

- Expertise: Experienced technicians possess in-depth knowledge of John Deere ECMs and the necessary skills to diagnose and repair complex issues.

- Genuine Parts: Reputable repair services use only genuine John Deere parts, ensuring compatibility and long-term reliability.

- Warranty: Most professional repairs come with a warranty, providing peace of mind and protection against future problems.

- Cost-Effective: Repairing an ECM is often significantly more cost-effective than replacing it with a new unit, especially considering the cost of programming a new ECM. A diagnostic fee is usually charged if the ECM is not repairable.

Conclusion

John Deere L16 ECM repair requires specialized knowledge and equipment. By understanding common problems and choosing a professional repair service, you can minimize downtime and ensure the optimal performance of your John Deere equipment. A properly functioning ECM is crucial for efficiency, fuel economy, and overall equipment reliability.