Tools and equipment are significant investments, whether you’re a professional mechanic or a dedicated DIY enthusiast. Ensuring their longevity and optimal performance means taking proper care of them. Effective maintenance not only saves you money in the long run by preventing premature replacements but also ensures your tools are always ready when you need them. Here’s a comprehensive guide on how to take care of your tools and equipment, keeping them in top shape for years to come.

1. Implement Regular Cleaning Practices

The most fundamental aspect of tool maintenance is cleanliness. After each use, tools can accumulate residue, dirt, and debris that can lead to corrosion and decreased efficiency. For instance, screwdrivers used in prying or pliers used on rusty components should be wiped down immediately after use to remove any stuck materials. Regularly cleaning your tools prevents buildup that can hinder their performance and lifespan. Use a clean cloth or brush to remove dust, grease, or any materials clinging to the tool surfaces. For tougher residues, a mild cleaning solution can be used, ensuring tools are dried thoroughly afterward to prevent rust.

2. Consistent Lubrication is Key

Lubrication is crucial for the smooth operation and longevity of many tools, especially those with moving parts. It minimizes friction, reduces heat buildup, and protects against wear and tear. Furthermore, a good lubricant acts as a barrier against moisture, preventing rust and corrosion, particularly in humid environments. The frequency and type of lubrication needed will vary depending on the tool and its usage. Consulting the manufacturer’s guide is always recommended to determine the best lubricant and schedule for each tool. Apply lubricant to joints, hinges, and moving parts to keep them functioning smoothly. For tools used less frequently, lubrication before storage can prevent parts from seizing up over time.

3. Sharpening for Optimal Performance

Cutting tools, such as chisels, blades, and drill bits, require regular sharpening to maintain their effectiveness. A sharp tool not only performs better but is also safer to use, requiring less force and reducing the risk of slippage and accidents. When you notice your tools are not cutting as cleanly or efficiently as they used to, it’s a clear sign they need sharpening. However, it’s crucial to sharpen tools correctly to avoid damaging them. Incorrect sharpening techniques can ruin the tool’s temper and edge geometry. If you’re unsure how to sharpen a specific tool, seek out tutorials or professional sharpening services to ensure it’s done properly.

4. Proper Storage Solutions

Toolbox and tools

Toolbox and tools

How and where you store your tools significantly impacts their condition. Tools should be stored in a controlled environment, ideally a cool, dry, and well-ventilated space, as recommended by experts. Avoid storing tools in direct sunlight or damp locations, as both can accelerate deterioration. Sunlight can degrade materials, while moisture is a prime catalyst for rust and corrosion. Invest in appropriate storage solutions such as toolboxes, cabinets, racks, or cases to keep your tools organized and protected from physical damage. Proper storage not only prevents damage from environmental factors but also safeguards tools from physical impacts, bending, and vibrations that can occur when they are left cluttered or exposed.

5. Regular Inspection and Proactive Maintenance

Even with meticulous care, tools can degrade over time. Regular inspections are vital to catch early signs of wear and tear, allowing for timely intervention and preventing minor issues from escalating into major problems. Make it a habit to inspect your tools before and after each use. Look for signs of damage such as cracks, loose parts, frayed cords, or dull edges. Addressing these issues promptly can extend the life of your tools and prevent potential safety hazards. Proactive maintenance, such as tightening loose screws, replacing worn parts, or re-oiling components, should be part of your routine tool care.

6. Consider Repair Services for Damaged Tools

It’s tempting to discard broken tools and replace them, but repair is often a more cost-effective and sustainable option. Many tools, even those that seem beyond repair, can be restored to working order by professional tool repair services. These services specialize in fixing a range of tools, from electric drills to grinders and more. Before you consider replacing a malfunctioning tool, explore tool repair services. Repairing tools not only saves you money but also reduces waste and is an environmentally responsible approach to tool ownership.

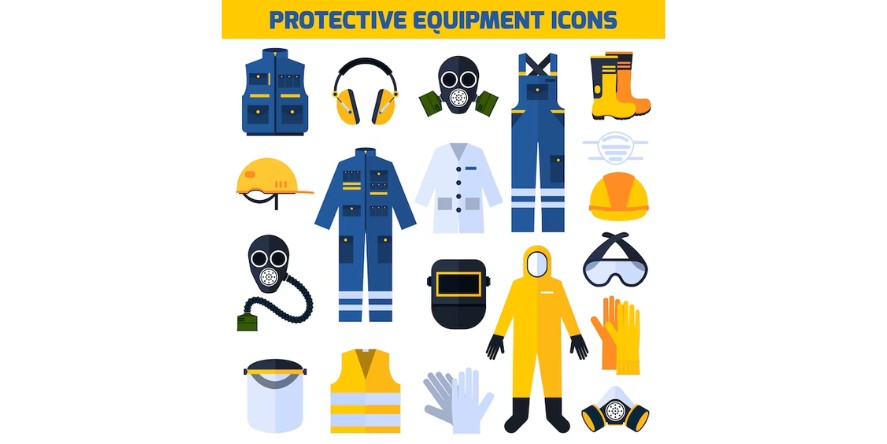

7. Prioritize Safety in Handling and Maintenance

Safety should always be paramount when using, storing, and maintaining tools. Always adhere to safety precautions to prevent accidents and injuries. This includes wearing appropriate safety gear such as safety goggles, gloves, and ear protection when operating or maintaining tools. Familiarize yourself with the operating guidelines for each tool and use them only for their intended purposes. Misusing tools or ignoring safety guidelines can lead to damage to the tools and, more importantly, personal injury.

By integrating these practices into your routine, you can significantly extend the life of your tools and equipment, ensuring they remain reliable and efficient for all your projects. Taking the time to properly care for your tools is an investment that pays off through improved performance, cost savings, and enhanced safety.