Freightliner trucks, like all modern vehicles, rely on complex computer systems to monitor and control engine performance. When a problem arises, these systems generate diagnostic trouble codes (DTCs) to help technicians pinpoint the issue. Understanding these codes, specifically the Suspect Parameter Number (SPN) within Freightliner codes, is crucial for effective diagnostics and repair. This guide will break down the components of Freightliner codes, focusing on the SPN and its role in troubleshooting.

Decoding Freightliner Diagnostic Trouble Codes (DTCs)

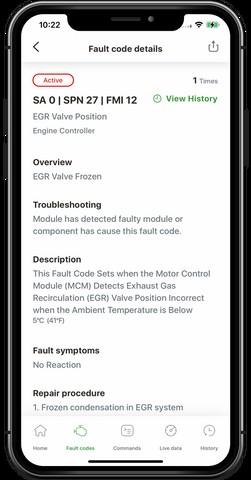

Freightliner DTCs follow the J1939 protocol, a standard communication format for heavy-duty vehicles. Each DTC consists of three key identifiers:

- SA (Source Address): Identifies the control module originating the code. For instance, SA 0 typically represents the Engine Control Module (ECM). Other common SAs include SA 11 for the Anti-lock Braking System (ABS), SA 3 for the Transmission Control Module (TCM), and SA 33 for the Body Control Module (BCM). Variations exist; Volvo trucks, for example, use SA 16 for the ECM.

- SPN (Suspect Parameter Number): This is the core of the DTC, pinpointing the specific component or operating condition causing the fault. SPN 3216, for example, indicates a problem with the Aftertreatment Intake NOx sensor.

- FMI (Failure Mode Indicator): Describes the nature of the fault. FMI values provide insights into the type of failure, such as circuit issues, component malfunctions, data errors, or out-of-range conditions.

Freightliner Codes SPN and FMI: A Deeper Dive

Understanding the relationship between the SPN and FMI is crucial. While the SPN identifies the potential problem area, the FMI provides context, guiding technicians toward a more precise diagnosis.

Common FMI Types and Their Meanings:

- Circuit Issues (FMI 3, 4, 5, 6): Indicate problems within the electrical circuit, such as open circuits, shorts to ground, or abnormal current levels. FMI 5, for example, suggests low current or an open circuit, often pointing to a broken or disconnected wire.

- Component Failures (FMI 7, 12): Signal a malfunctioning component. FMI 12 typically signifies a bad device or component requiring replacement. FMI 7 suggests a non-responsive or out-of-adjustment component.

- Data Communication Errors (FMI 9, 10): Relate to problems with the Controller Area Network (CAN), the communication system between the vehicle’s various modules. FMI 9 indicates an abnormal update rate, while FMI 10 signals an abnormal rate of change in data. This often points to communication issues between sensors and control modules.

- Out-of-Range Conditions (FMI 0, 1): Indicate that data received is either above or below the normal operating range. These often occur in the aftertreatment system, such as with the Diesel Particulate Filter (DPF) or Exhaust Gas Recirculation (EGR) system. FMI 1 signifies data below the normal range.

- Special Instructions (FMI 14): Requires consulting manufacturer-specific documentation for detailed diagnostic procedures.

Conclusion: Mastering Freightliner Codes SPN for Efficient Repairs

Freightliner codes, particularly the SPN and FMI combination, provide vital clues for diagnosing truck problems. By understanding the meaning of these codes, technicians can efficiently troubleshoot issues, minimize downtime, and ensure the safe and reliable operation of Freightliner trucks. Always consult official Freightliner documentation for precise diagnostic and repair procedures related to specific SPN and FMI combinations.