The Audi EA835 engine, first introduced in 1990, laid the groundwork for the modern V6 engines found in many Audi vehicles today. Understanding the EA835 and its associated Self-Study Program (SSP) is crucial for comprehending the evolution of these powerplants, particularly the supercharged EA837. This article delves into the key features and common issues of the EA837 TFSI, drawing information from the Ea835 Ssp and practical experience.

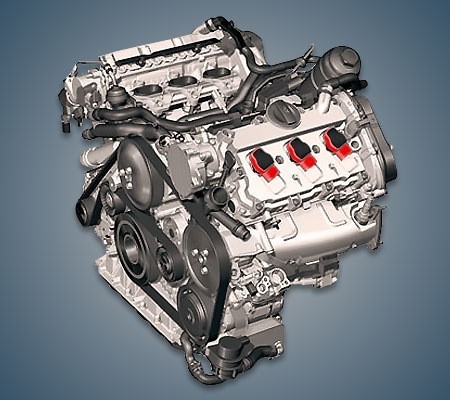

The EA837 TFSI, found in vehicles like the 2011 Audi A7 Sportback 3.0 TFSI, shares its roots with the naturally aspirated 3.2 FSI (AUK/BKH). As detailed in the EA835 SSP, Audi engineers adapted the 3.2 FSI architecture to accommodate a supercharger, specifically an Eaton Roots-type supercharger. This four-lobe, twin-screw design provides consistent boost via a belt drive connected to the crankshaft. This results in the smooth, linear power delivery that characterizes the 3.0 TFSI.

While superchargers were once dominant in performance applications, modern turbochargers offer superior efficiency. However, the Eaton supercharger in the EA837 remains a testament to Audi’s engineering heritage and provides a unique driving experience. The 1:2.5 pulley ratio contributes to the engine’s responsiveness, though aftermarket modifications often alter this ratio for increased boost. The EA835 SSP provides detailed specifications on the supercharger system, including its integration with the engine management system.

A comprehensive understanding of the EA835 SSP reveals several notable differences between various EA837 engine variants (from AUK to CREC), highlighting the need for potential block modifications. The original aluminum closed-deck design presented challenges for cylinder liner installation, potentially leading to concerns about engine longevity.

The first-generation 3.0 TFSI engines, however, weren’t without their flaws. Common issues, as documented by experienced mechanics and potentially referenced in the EA835 SSP, include:

- Cylinder Scoring (Nikasil Coating Issues): The Nikasil cylinder lining is susceptible to damage if not properly maintained or operated under adverse conditions.

-

Oil Separator Problems: The original oil separator (06E 103 547 S) is prone to failure and should be replaced with a genuine Audi part with a functioning PCV valve.

-

Oil Channel Valve Malfunction: Faulty oil channel valves can lead to oil starvation during engine startup. Replacing these valves (059 103 175 F) is crucial for engine health.

-

Timing Chain Tensioner Issues: Similar to the 3.2 FSI, the EA837 can suffer from timing chain tensioner failures, often exacerbated by poor oil quality, low-quality fuel, and issues with fuel injectors or the high-pressure fuel pump.

- Exhaust Bellows Failure: Replacing worn exhaust bellows with high-quality parts (e.g., MFP083) is essential to prevent exhaust leaks.

-

Thermostat, Water Pump, and Cylinder Head Crossover Pipe Failures: These components are known to fail prematurely and require regular inspection.

-

Supercharger Component Issues: The supercharger itself and its associated components can experience wear and tear, requiring maintenance or replacement.

-

FSI Fuel Injector Sensitivity: The FSI fuel injectors are highly sensitive to fuel quality and can be prone to clogging, potentially leading to engine damage.

Understanding the EA835 SSP and the evolution of the EA837 allows for informed maintenance and repair decisions. While the 3.0 TFSI offers impressive performance, addressing these potential issues is critical for ensuring longevity and reliability. Future articles will explore specific repair procedures for these common problems.