A faulty DOC (Diesel Oxidation Catalyst) inlet temperature sensor can cause a range of issues in diesel engines, from low power to inhibited regeneration. This case study examines a real-world diagnostic scenario involving a John Deere skid steer, highlighting the importance of data analysis and component knowledge in troubleshooting. Understanding the role and function of the Doc Inlet Temp Sensor is crucial for effective diesel engine repair.

Pinpointing the Problem: DOC Inlet Temp Sensor

The John Deere 320E skid steer presented with several concerning symptoms: reduced power, a clogged DPF (Diesel Particulate Filter), and flashing diagnostic trouble codes (DTCs). The DTCs pointed towards an extremely high DOC inlet temperature and an out-of-range high signal. This immediately focused the diagnostic efforts on the DOC inlet temp sensor as the primary suspect. A faulty doc inlet temp sensor reading can prevent the DPF from regenerating properly.

Utilizing Live Data for Diagnostics

Leveraging the John Deere diagnostic software, a live data recording of various engine parameters was captured. This allowed for a remote diagnosis of the issue. Initially, around 70 data PIDs (Parameter IDs) were recorded, but the focus quickly narrowed down to the essential ones related to the DOC inlet and outlet temperatures and their corresponding voltages.

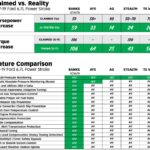

A key observation was the stark contrast between the DOC inlet and outlet temperatures. The inlet temperature was pegged at the maximum default value of 662°F with a voltage of 1.7V, while the outlet temperature was a reasonable 419°F at 1V. This discrepancy, coupled with the known 5V operating range of the thermocouples, signaled a potential problem with the DOC inlet temp sensor itself.

Further analysis of consecutive data readings revealed fluctuating voltage inputs for the DOC inlet temperature while the temperature reading remained fixed at the maximum value. This indicated that the ECU (Engine Control Unit) was rejecting the rapidly changing voltage signals as irrational and defaulting to the maximum temperature value. Suspicion fell upon a faulty DOC inlet temp sensor element making intermittent contact with the sensor body.

Confirming the Diagnosis and Resolution

A simple physical test was conducted: lightly tapping the DOC inlet temp sensor. After a couple of taps, the voltage stabilized at 4.95V, confirming the suspicion of a broken internal element within the sensor. While not performed in this instance, a further verification test could involve unplugging the sensor and observing the data PID changes, followed by grounding the signal wire with a test lamp or resistor to confirm wiring and module integrity. This highlights the importance of thorough testing when dealing with potential sensor issues.

A new DOC inlet temp sensor was subsequently installed, resolving the issue. The machine successfully completed a service regeneration and returned to normal operation.

The Importance of Data and Knowledge in Diagnostics

This case study underscores the critical role of data recording and analysis in modern diesel engine diagnostics. It also demonstrates how a thorough understanding of component operation and failure modes can lead to efficient and accurate troubleshooting. Knowing how a doc inlet temp sensor works, its typical failure modes, and how it impacts the overall system allows for quicker diagnosis and repair. By eliminating the impossible through data analysis and applying knowledge of the system, the improbable solution – a faulty DOC inlet temp sensor – became the undeniable truth.