The Caterpillar C15 engine, particularly the mid-2000s models, often sparks debate regarding its turbocharger configuration: single or “twin” turbo. While the factory Acert system is frequently called “twin turbo,” it’s crucial to understand that it’s not a true twin-turbo setup. This article delves into the differences between the C15 single and compound turbo systems, outlining their advantages and disadvantages.

Decoding the C15 Acert “Twin Turbo” (Compound Turbo) System

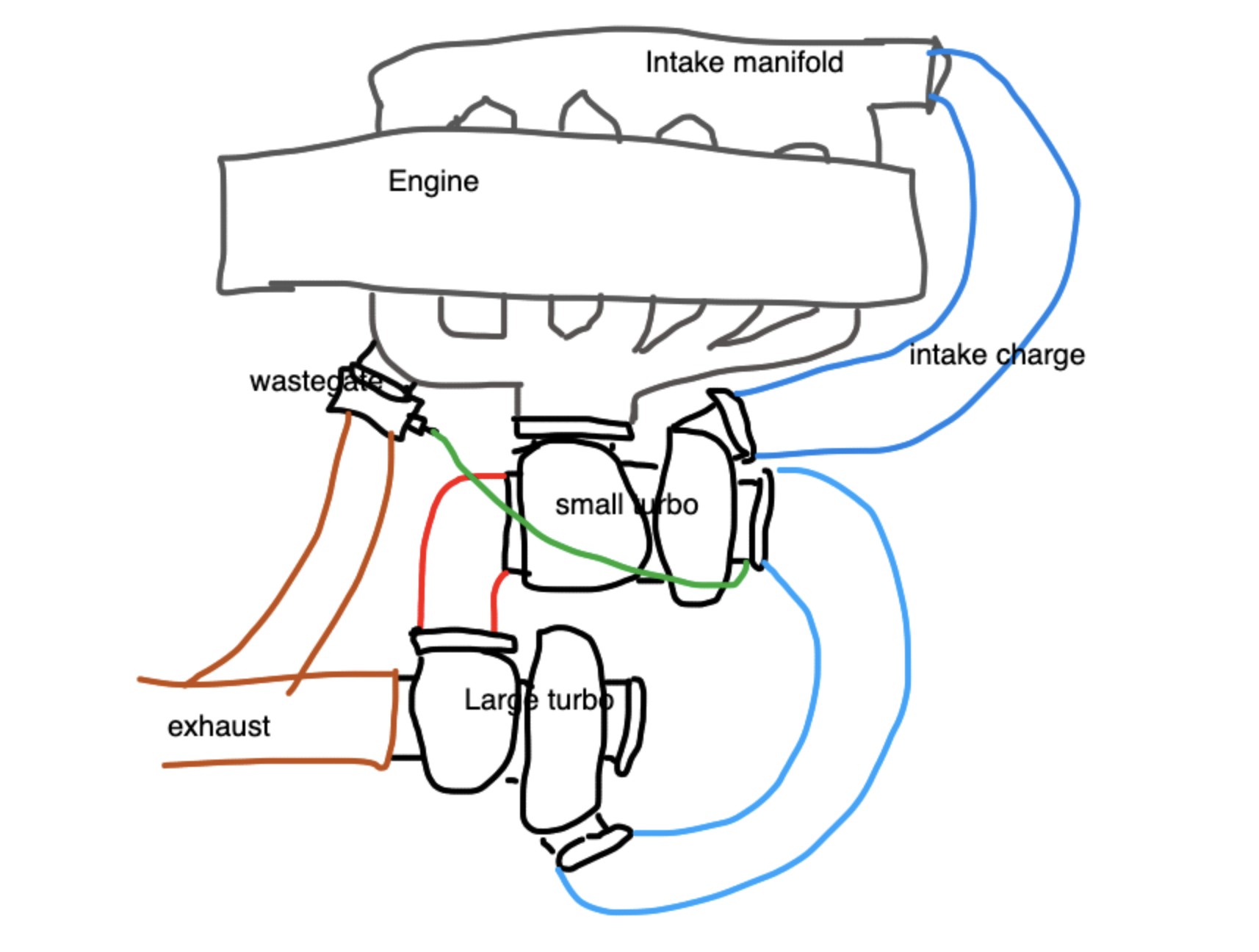

The Acert system utilizes a compound turbo configuration, employing a high-pressure (HP) and a low-pressure (LP) turbocharger working in series. Contrary to common assumptions, the smaller turbo is the HP turbo, mounted directly to the exhaust manifold. It receives exhaust gases first, spooling up quickly and providing initial boost. The larger turbo is the LP turbo. It receives exhaust gases after they exit the HP turbo, contributing to boost pressure primarily in the mid and upper RPM range.

This sequential arrangement, where the LP turbo boosts the air already compressed by the HP turbo, is called compounding. The air intake connects to the LP turbo’s inlet, and its outlet feeds into the HP turbo’s inlet, resulting in significantly increased boost pressure. This setup enhances efficiency and provides a broader power band compared to a single turbo. However, it introduces complexity and potential maintenance challenges.

The C15 Single Turbo System: Simplicity and Serviceability

Before the Acert, the C15 employed a single turbocharger system, often found in the “E models.” These engines, similar to the 3406E, utilized a straightforward single turbo setup. Many Acert owners consider converting back to a single turbo for its simplicity and reduced maintenance costs.

A single turbo eliminates the need for multiple turbos, bellows, and the pre-cooler system associated with the compound setup. This simplification results in a less cluttered engine compartment, easing maintenance access. Moreover, single turbo systems are more common, making roadside repairs and parts sourcing easier.

C15 Twin Turbo Considerations: Efficiency vs. Simplicity

The choice between a single or compound turbo for a C15 boils down to individual priorities. Compound turbos offer superior efficiency and broader power delivery, making them ideal for applications demanding optimal fuel economy and performance across a wide RPM range.

Conversely, single turbo systems provide simplicity, easier maintenance, and potentially lower repair costs. While perhaps less efficient overall, they offer a robust and readily serviceable solution. The abundance of single turbo options also allows for performance upgrades and easier parts replacement. Ultimately, the “best” choice depends on individual operational needs, maintenance preferences, and performance expectations. Whether prioritizing fuel efficiency or ease of maintenance, understanding the nuances of each system is crucial for making an informed decision.