Automating tasks in SOLIDWORKS can significantly boost productivity. One powerful feature, Auto Solidworks, specifically targets the often tedious process of fixing broken mates in assemblies. This article explores the functionality of Auto SOLIDWORKS, demonstrating its capabilities and limitations through a practical example of designing a simple box assembly.

Understanding the Power of Auto SOLIDWORKS

Broken mates in large assemblies can be a nightmare, leading to performance issues and hindering troubleshooting. Auto SOLIDWORKS aims to alleviate this pain by intelligently identifying and fixing broken relationships between parts. It leverages SOLIDWORKS’ understanding of geometric constraints to suggest and apply appropriate fixes, drastically reducing manual intervention.

Testing Auto SOLIDWORKS: A Box Assembly Case Study

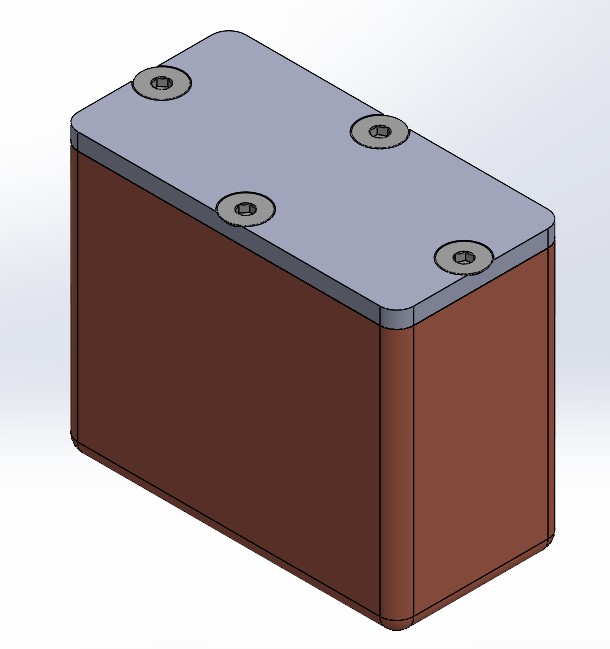

To evaluate Auto SOLIDWORKS, we’ll use a simple box assembly with a lid, fasteners, and strategically introduced errors. Initially, the box dimensions are incompatible with the chosen fasteners, leading to broken mates.

Modifying the box dimensions to accommodate the correct fasteners immediately triggers broken mate errors in SOLIDWORKS.

Replacing the lid with a new part designed to fit the revised box dimensions requires further adjustments.

Even after replacing the lid, misalignments persist, resulting in more broken mates.

Auto SOLIDWORKS in Action: Fixing Broken Mates

At this point, Auto SOLIDWORKS comes into play. Surprisingly, fixing a single broken mate using traditional methods often triggers a cascade of automatic fixes for other related mates.

Further testing reveals Auto SOLIDWORKS can successfully resolve a range of broken mate scenarios, including coincident, concentric, and distance mates.

However, Auto SOLIDWORKS has limitations. Ambiguous situations, such as choosing between two potential mating holes, require manual intervention.

Fastener placement can also pose challenges. Utilizing pattern-driven component patterns can mitigate these issues.

Conclusion: Auto SOLIDWORKS – A Powerful Tool with Limitations

Auto SOLIDWORKS revolutionizes assembly management by automating mate repair, significantly improving efficiency. While not a perfect solution for all scenarios, its intelligent capabilities dramatically reduce manual effort and streamline the design process. Understanding its limitations empowers users to leverage its full potential and tackle complex assemblies with confidence.