The 324 Cat Excavator is a powerful and versatile machine designed for a wide range of applications. This article provides a detailed overview of the 324 Cat Excavator, covering its key features, benefits, and specifications. From its robust engine and advanced hydraulics to its comfortable operator station and convenient serviceability, the 324 Cat Excavator is built to deliver exceptional performance and productivity.

Engine and Performance

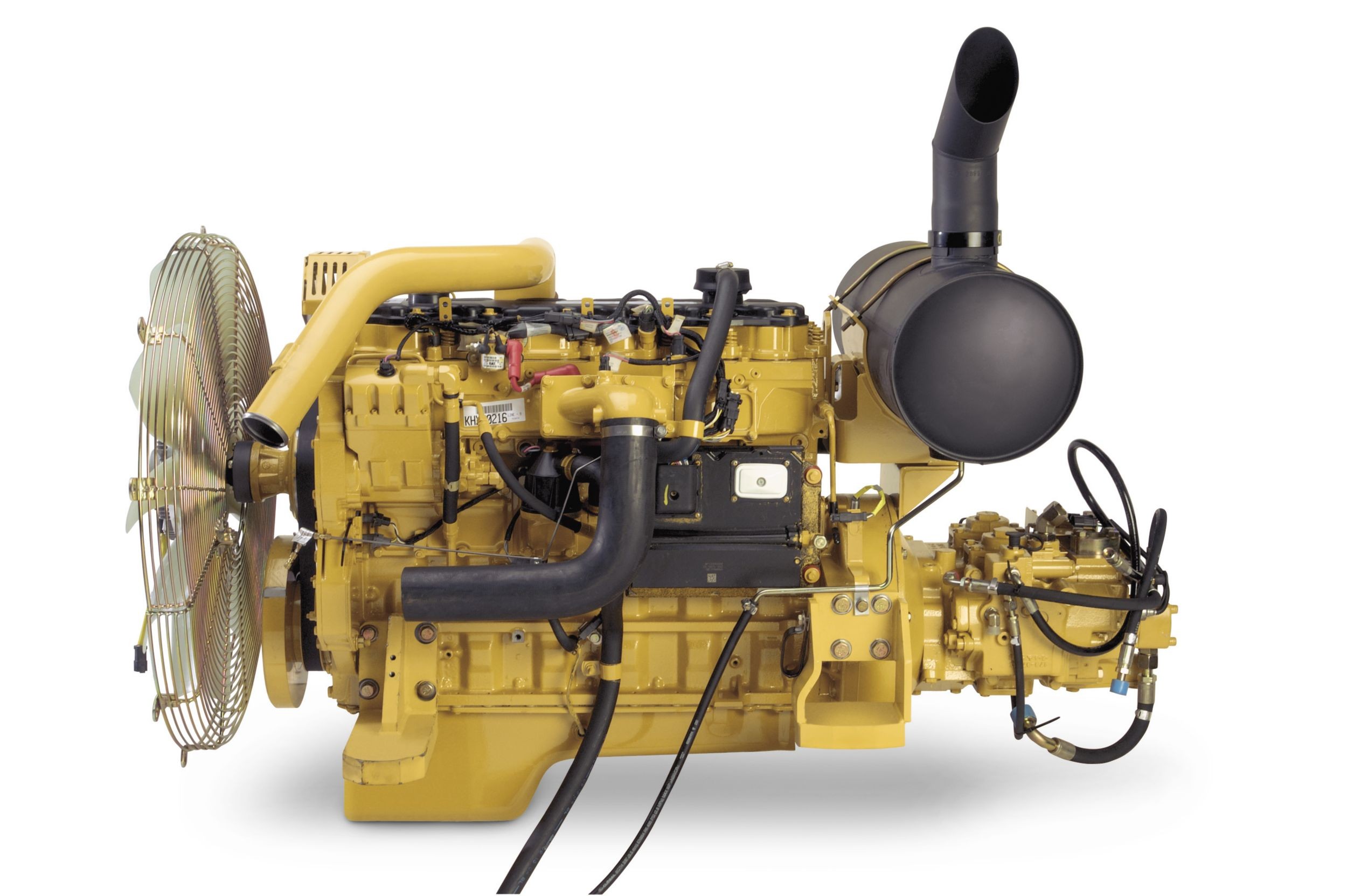

The 324 Cat Excavator is powered by a Cat C7 engine with ACERT™ Technology. This advanced engine technology optimizes fuel efficiency and reduces emissions while delivering reliable power. The ADEM™ A4 electronic control module manages fuel delivery precisely, ensuring optimal performance and responsiveness in various operating conditions. The engine’s multiple injection fuel system lowers combustion chamber temperatures, resulting in cleaner emissions and maximizing fuel efficiency.

Hydraulic System Efficiency

The hydraulic system of the 324 Cat Excavator is designed for maximum efficiency and productivity. Strategically placed components, including the main pumps, control valves, and hydraulic tank, minimize friction loss and pressure drops. The hydraulic cross-sensing system utilizes both hydraulic pumps to their full potential, enabling faster implement speeds and quicker pivot turns. Boom and stick regeneration circuits further enhance efficiency by saving energy during boom-down and stick-in operations.

Operator Comfort and Control

The 324 Cat Excavator features a spacious and comfortable operator station designed to minimize fatigue and maximize productivity. The adjustable monitor provides clear visibility and displays information in multiple languages. Joystick controls with low lever effort and ergonomic design reduce operator strain. Automatic climate control ensures a comfortable working environment, regardless of external conditions. The cab’s robust construction and viscous rubber mounts minimize noise and vibration, further enhancing operator comfort.

Structures and Undercarriage

The 324 Cat Excavator boasts a robust structure built for durability and reliability. Robotic welding ensures high-quality welds with superior penetration compared to manual welding. The durable Cat undercarriage absorbs stresses and provides excellent stability, even in challenging terrain. The reach boom offers optimal digging envelopes with various stick options, while the mass excavation boom delivers higher digging forces for demanding applications.

Work Tools and Versatility

The 324 Cat Excavator supports a wide range of work tools and attachments, enhancing its versatility for various tasks. Heavy-duty buckets, general-purpose buckets, and rock buckets are available for different digging and loading applications. Caterpillar Ground Engaging Tools (GET) provide optimal penetration and durability. Hydraulic hammers, thumbs, multi-processors, and other attachments further expand the machine’s capabilities.

Serviceability and Maintenance

The 324 Cat Excavator is designed for easy serviceability and maintenance, minimizing downtime and maximizing productivity. Ground-level access to key service points simplifies routine maintenance tasks. Extended service intervals reduce the frequency of maintenance, further enhancing machine availability. The air filter compartment, pump compartment, and radiator compartment are easily accessible for convenient servicing.

Conclusion

The 324 Cat Excavator is a reliable, powerful, and versatile machine built to meet the demands of various construction and excavation projects. Its advanced engine technology, efficient hydraulic system, comfortable operator station, and convenient serviceability contribute to its exceptional performance and productivity. The wide range of available work tools further enhances its versatility, making the 324 Cat Excavator a valuable asset for any construction fleet.